Efficiency & versatility!

By taking on short projects our creativity is constantly tested across multiple fields.

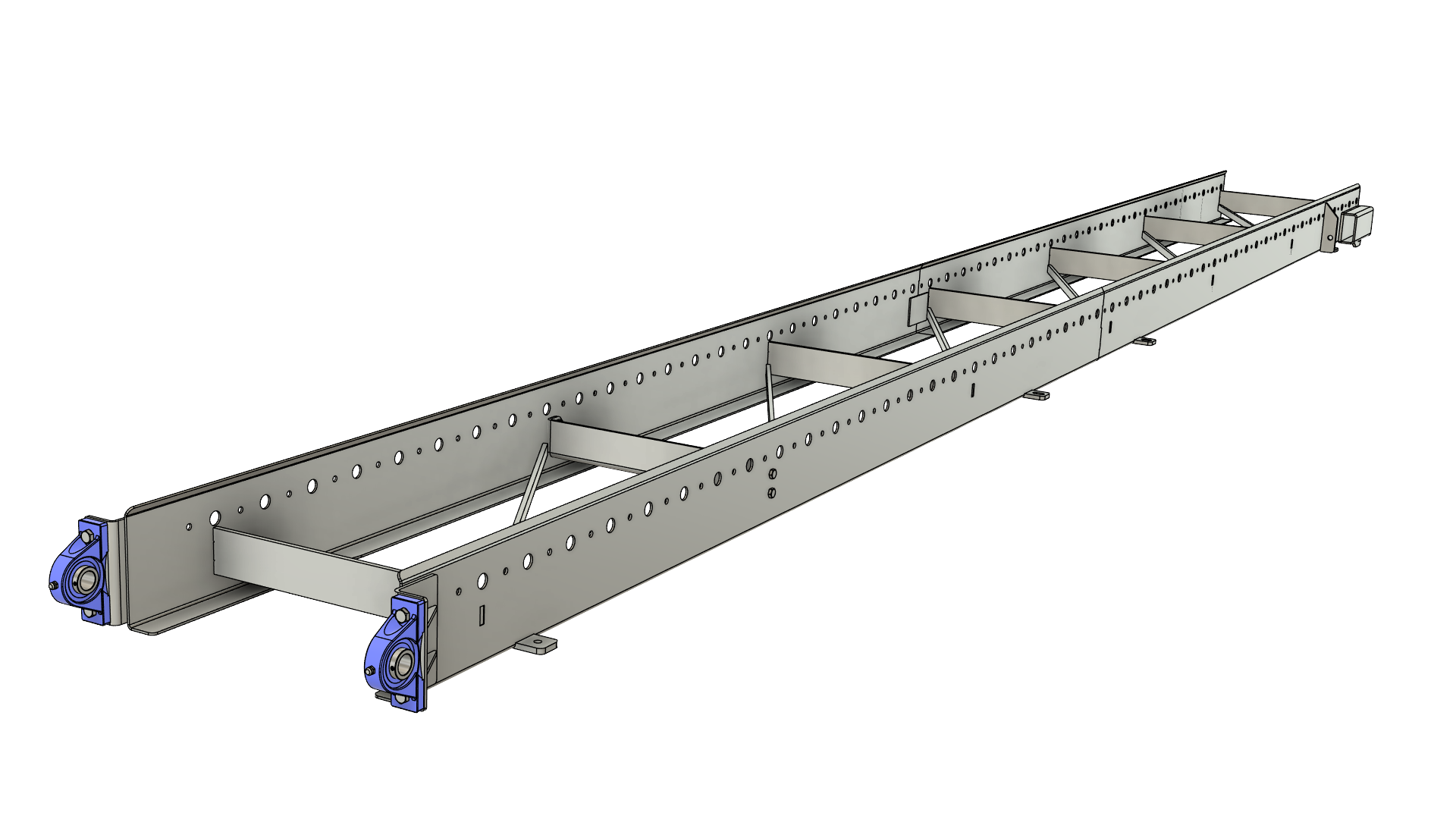

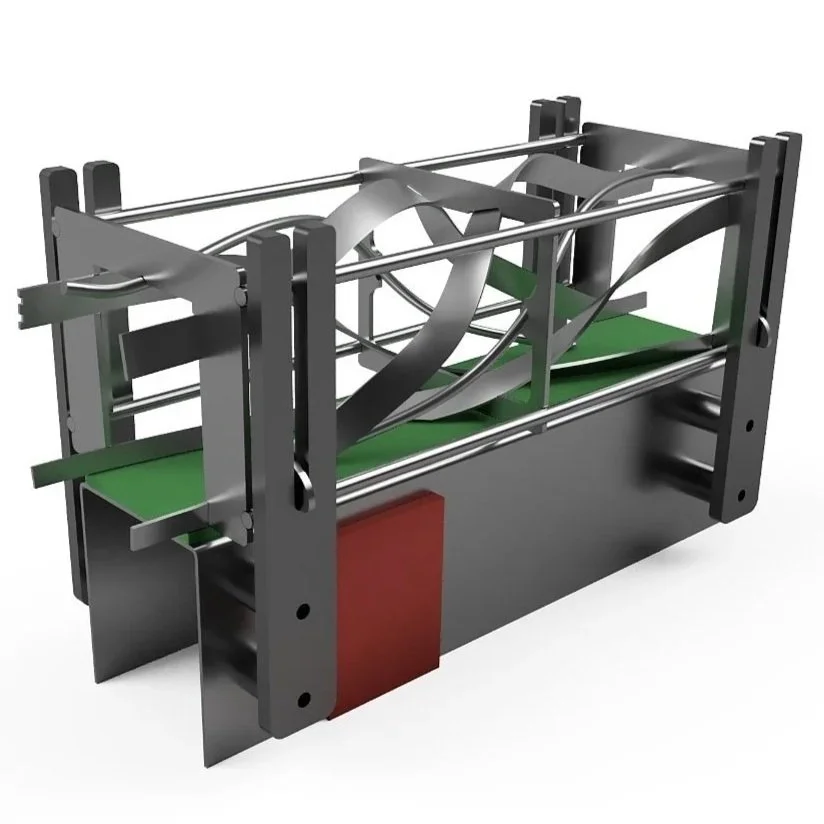

Modeling of an old conveyor

A relatively simple sheet metal construction. The key here was estimating the correct dimensions on rusted features.

Added positioning features in the sheet metal to make welding easier.

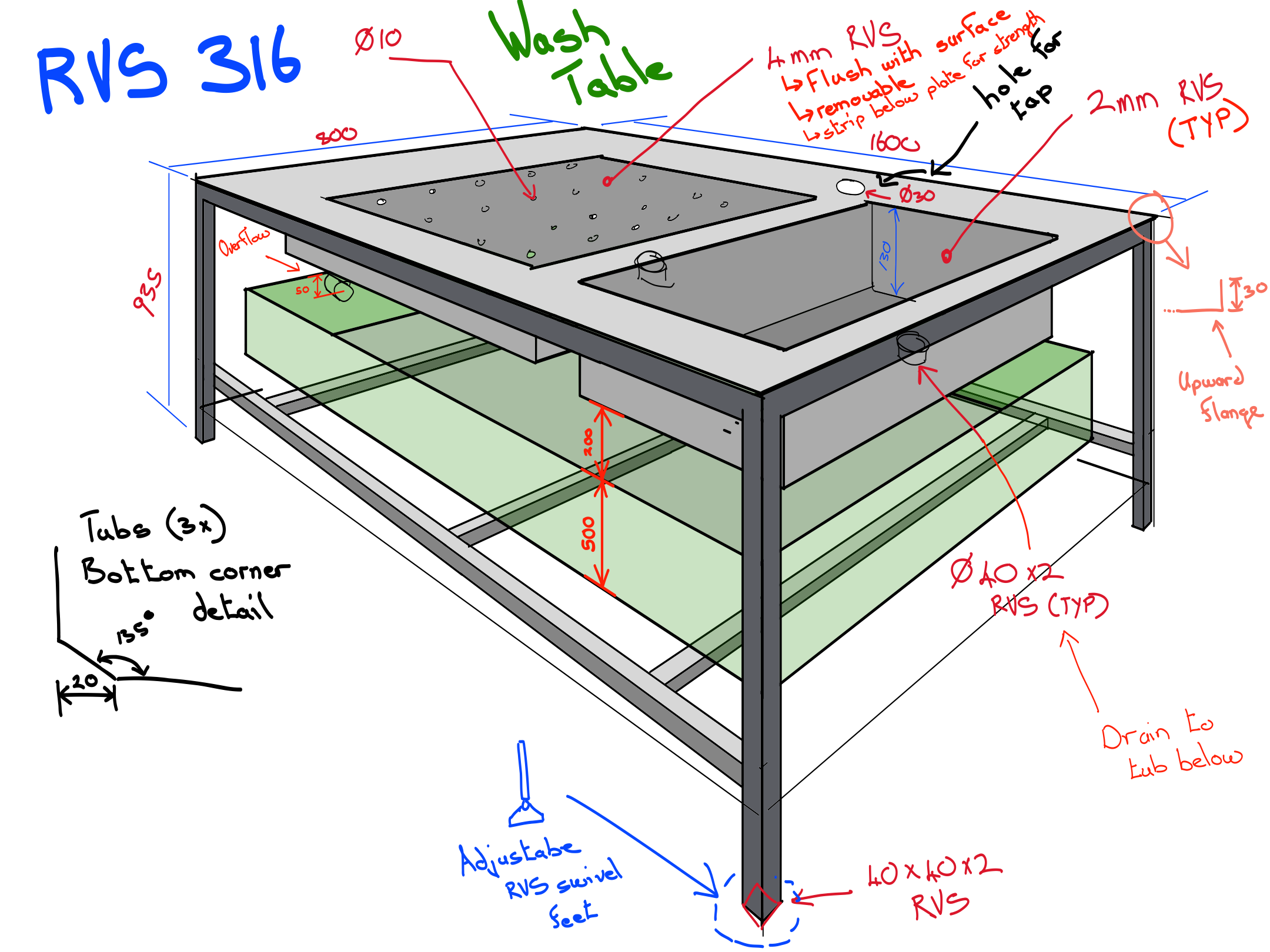

Modeling of a rock cleaning table

A consultation does not have to be lengthy. After a 30 min discussion a concept sketch was created, details were added and the client approved the design stage.

Using the concept sketch and a short project definition document Lepa could easily complete the design for client approval. Jacob was then the final quality control point of the design and drawings before the design package was delivered to the client.

Bracket for solar panel cables

A simple request. A small part. Thousands made.

The commercially available solutions were bulky and expensive. A more streamlined stainless steel bracket was engineered with custom tooling to quickly and cheaply produce the part at half the price.

A quick showcase of the bracket and forming steps.

Olive can inverter

A fun project to do. A vinyard that produces olives wanted to showcase the canning process. The olive cans are placed upside down for washing and drying. They then need to be fliped/inverted for the filling step.

The olive cans are very lightweight when empty. Adding jet’s of air get’s them across the inverter.

Do you need help with a short project?

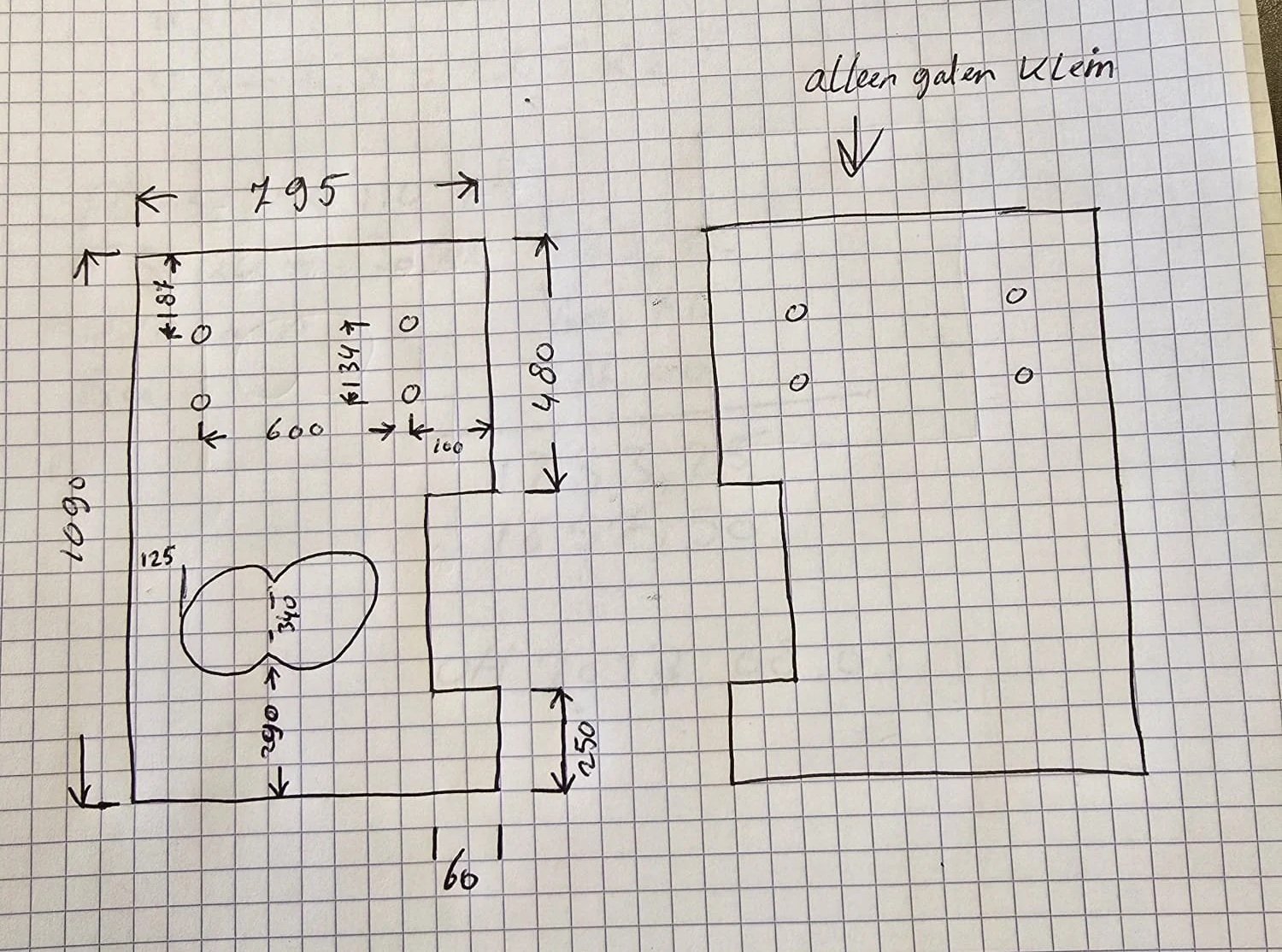

Machine panels

A nice example of remote design. A simple sketch, a photo and a short description. A short moment later, a complete design with manufacturing files.

Rollers for Golf Course lawn mowers

Large mowers on a golf course makes use of roller, either smooth or profiles. The maintenance manger of a course kept repairing the rollers every 6 months as it was cheaper than to import OEM rollers from the Americas.

A new design was created with double bearings and an extended grease labyrinth to keep dirt way from the bearings. The new rollers is now lasting years instead of months.

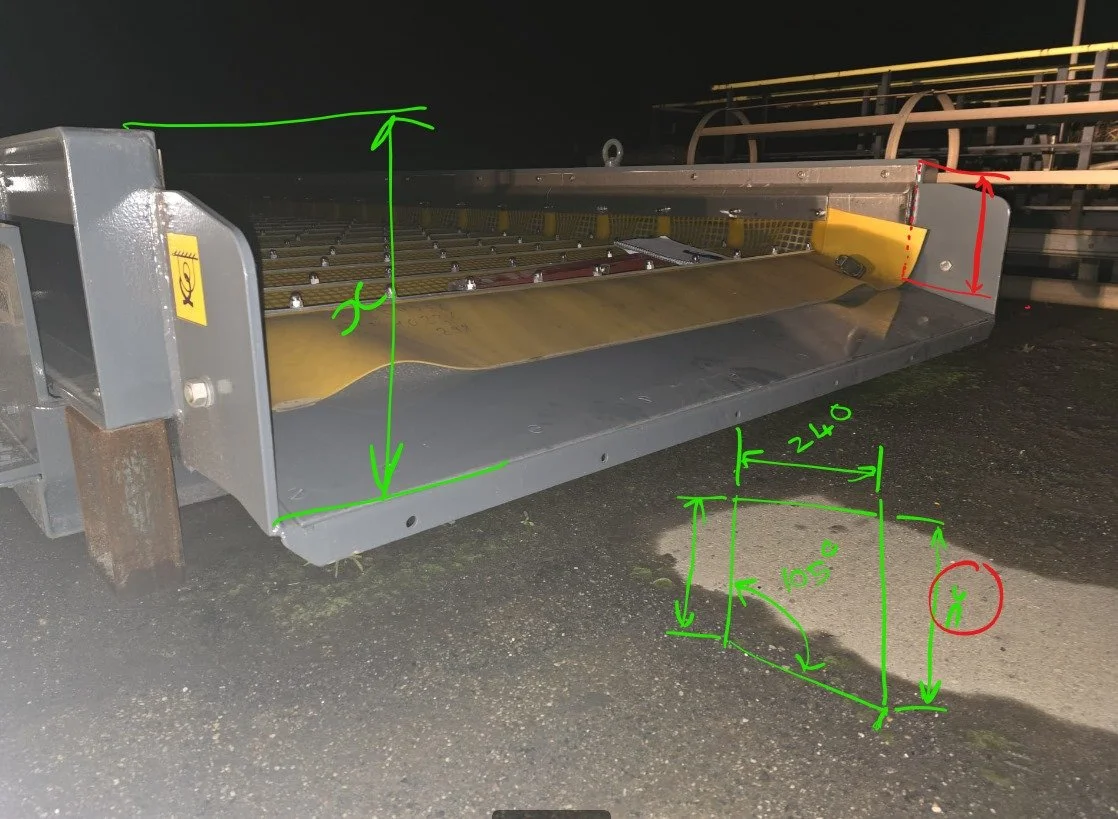

Interface assembly between old & new

A new conveyor needed an adaptor plate in order to interface with the old equipment on the Heros site.

A relatively simple design, but a good example of what can be achieved with WhatsApp and some mechanical intuition.

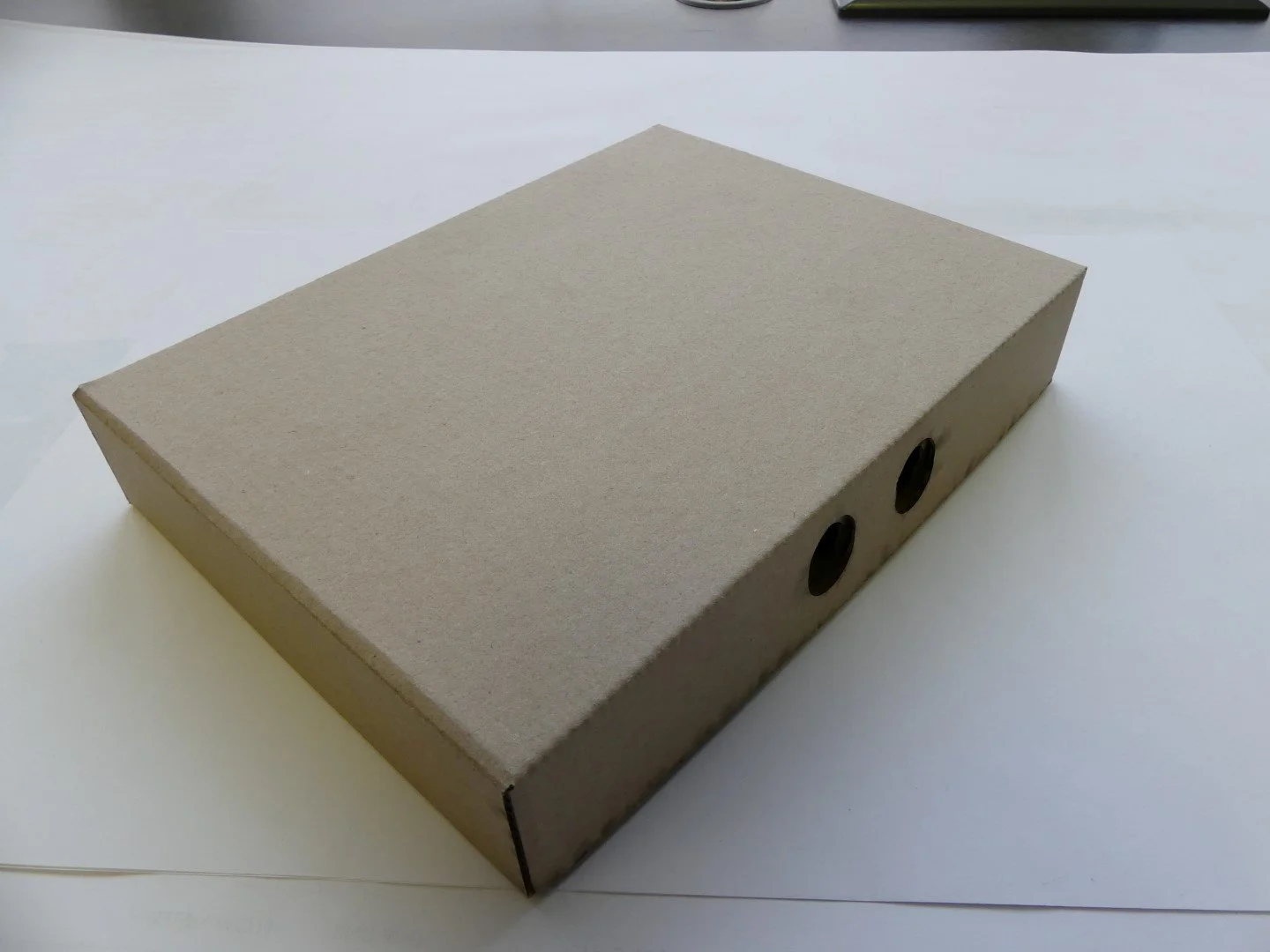

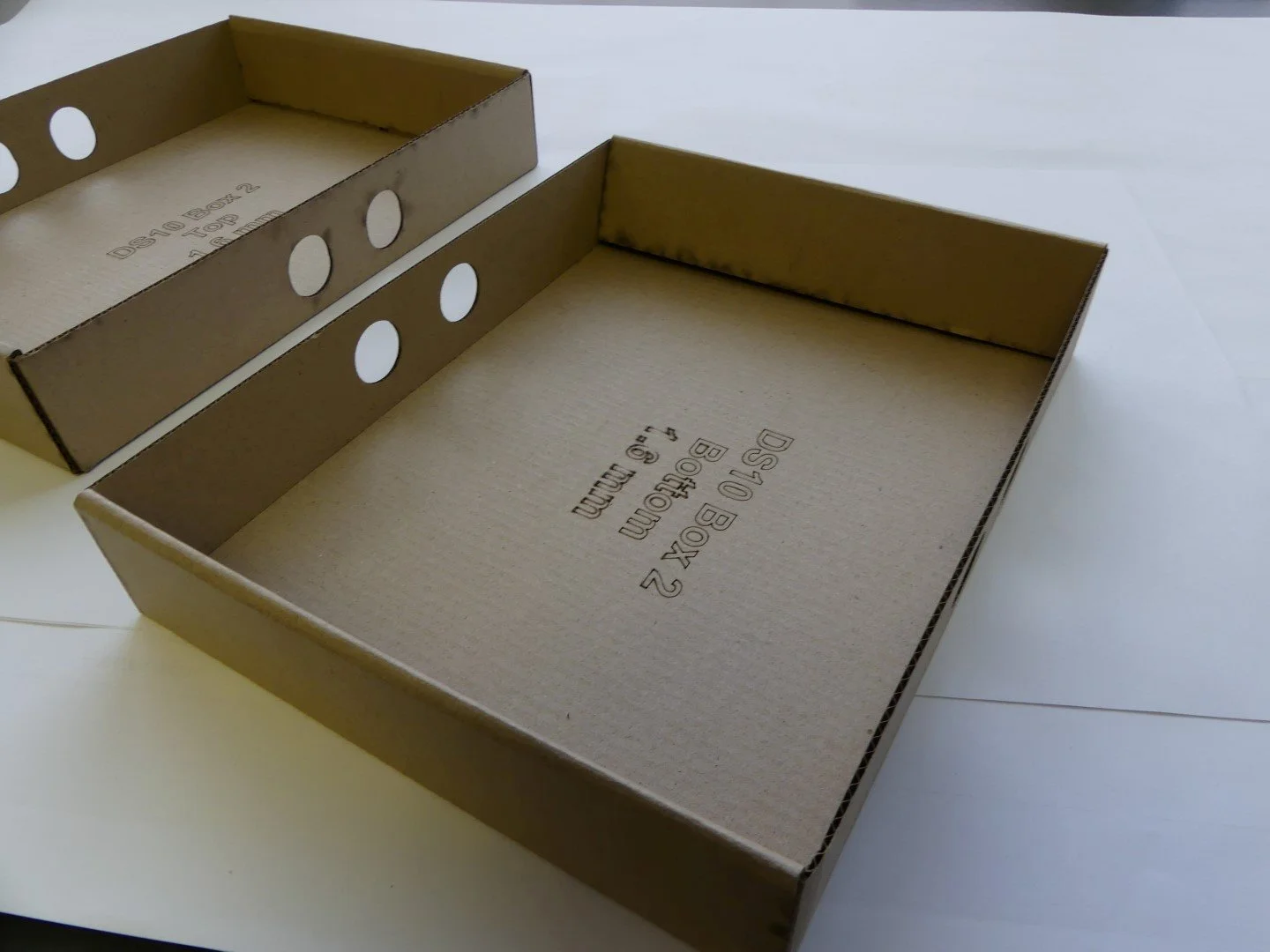

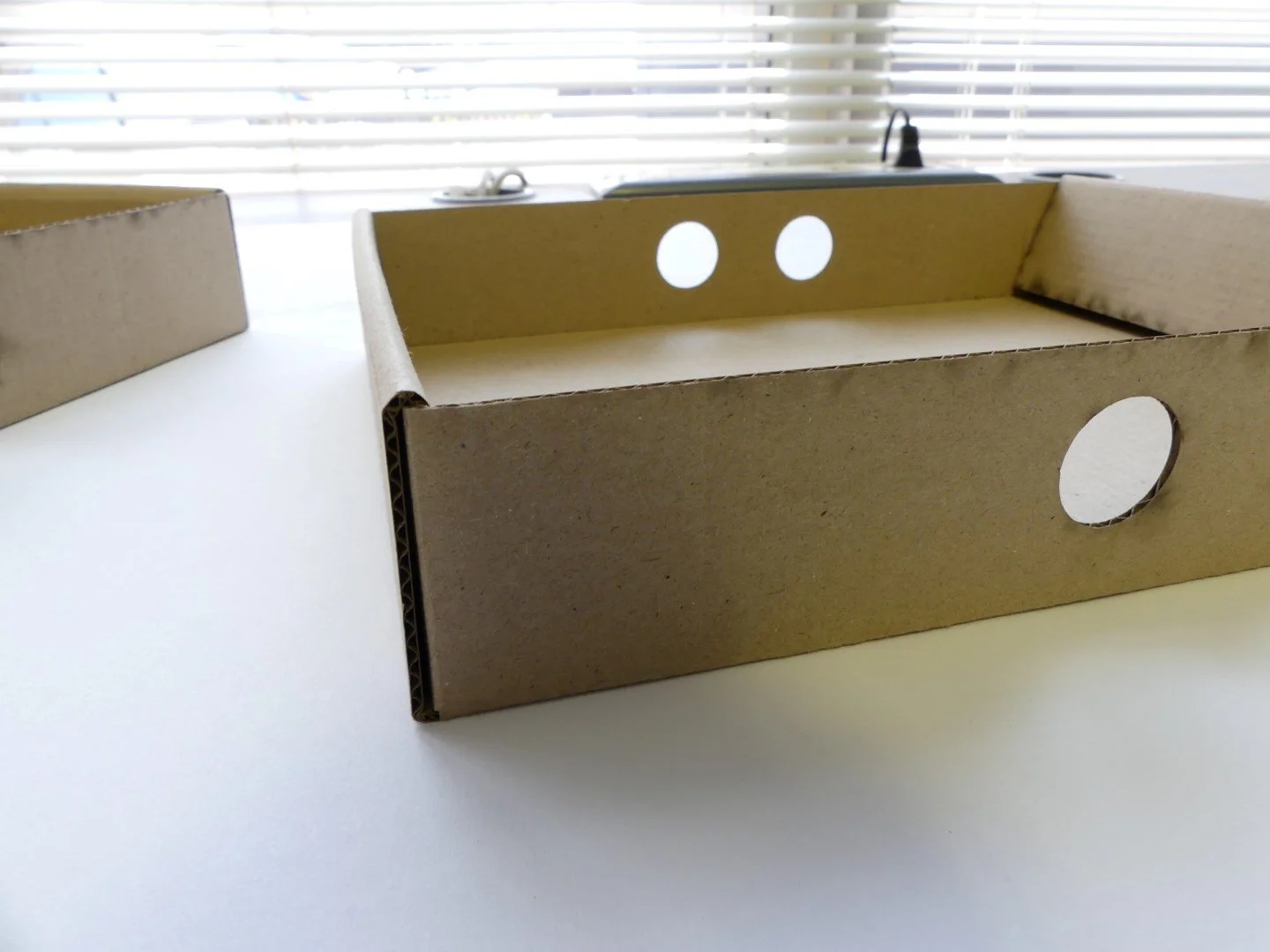

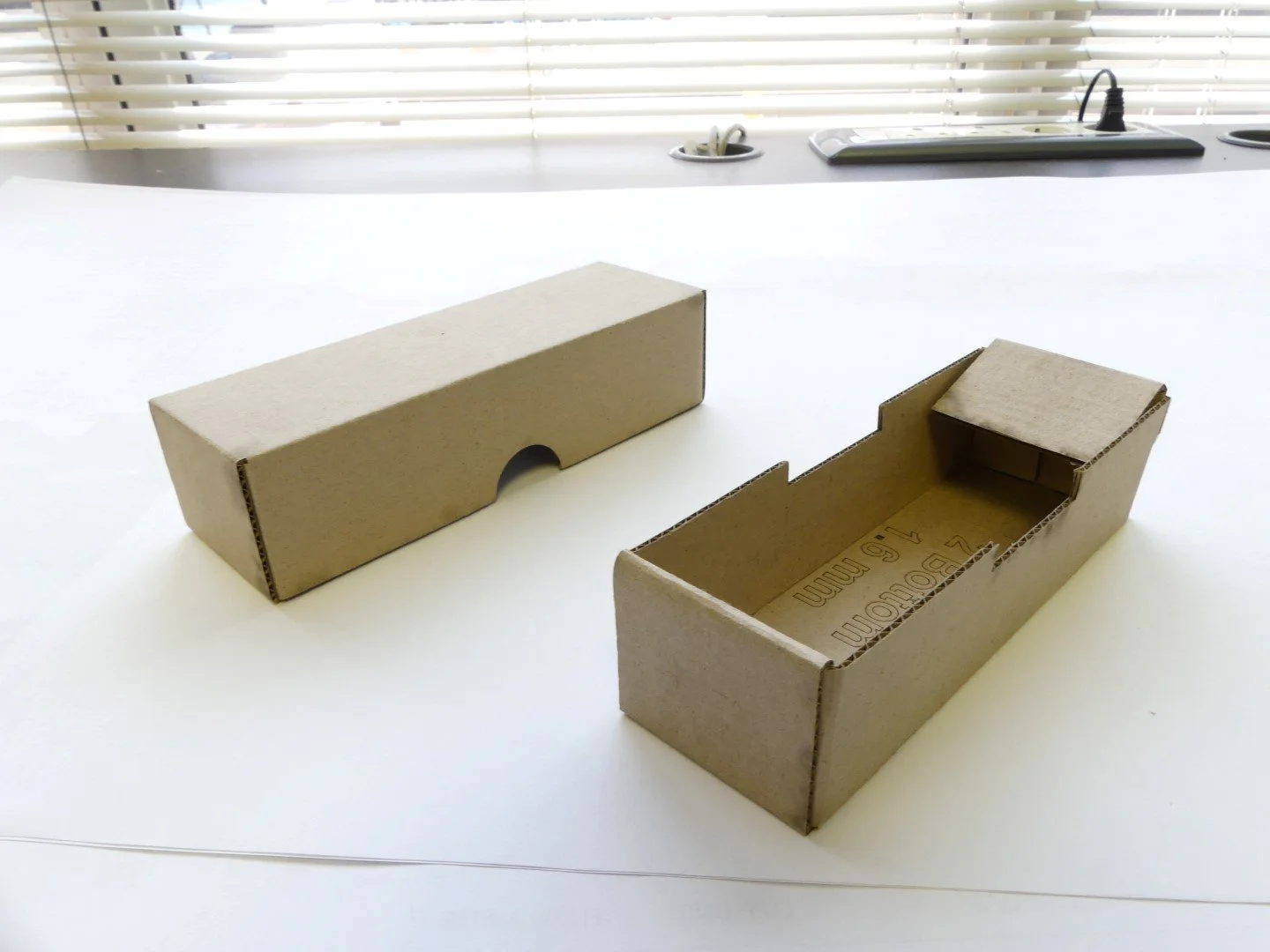

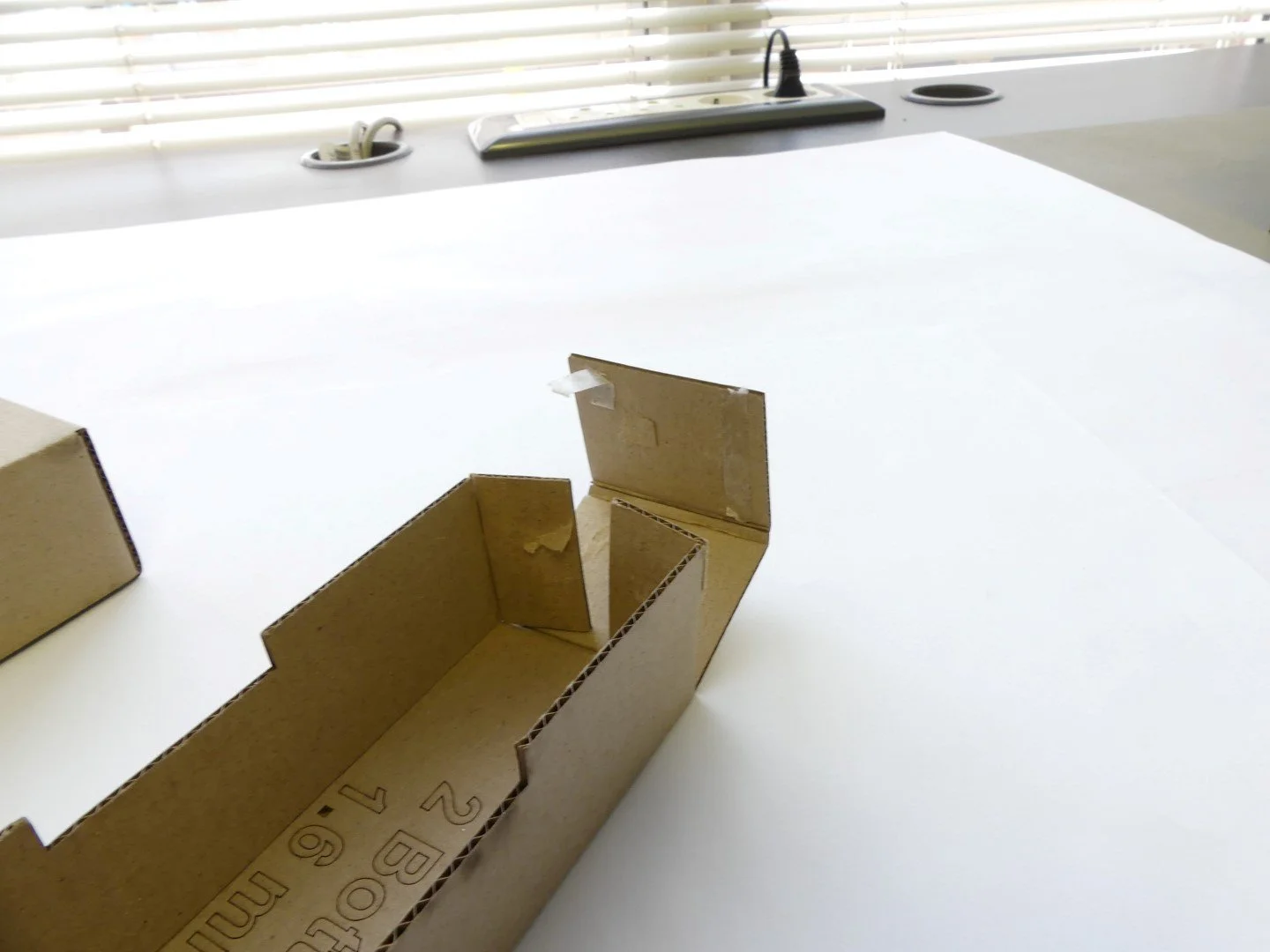

Prototyping cardboard packaging

The idea is simple. You are launching a product and you want to have custom packaging made. Before you invest in custom tooling with a packaging manufacturer you prototype your designs using laser cutting and sheet metal tools in your CAD software

Do you need help with a short project?

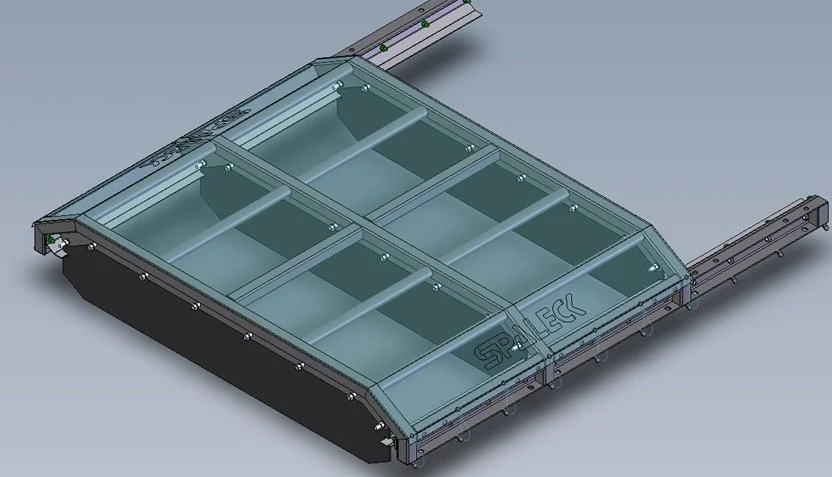

Spaleck Frame

Corrosion and age is a serious problem on Heros. These frames needed renewing and the original design was not available anymore.

This is a more complicated design and was done remotely with WhatsApp communication and some mechanical intuition.

Heros material shoot

A site visit on short notice. An old section was going to be removed and a new funnel/shoot was needed to guide the processed material from the top conveyor to the bottom one.

Because you have to fit something into an existing environment all structures, obstructions and installation limitations need to be considered.

Can inverter

What is the purpose of a can inverter?

Well, canning lines produces canned products for multiple clients and depending on the clients wishes for where the best before date should be located th e can is either inverted or not.

The trick here is to tip the can first and then positioning a guide to lift the can from the conveyor. The cans from the rear then pushes the cans through the inverter.